| Model | DCGF14-12-5 | DCGF18-18-6 | DCGF24-24-8 | DCGF32-32-10 | DCGF40-40-10 | DCGF50-50-10 |

| Production Capacity:500ml(B/H) | 3000 | 5000 | 7000 | 10000 | 14000 | 17000 |

| Filling precision | ≤±3mm | |||||

| Suitable bottle | Round or square shaped bottle | |||||

| PET Bottle | Bottle Diameter:Ф50~Ф100 Bottle Height:150mm~330mm | |||||

| Suitable Cap Standard | Plastic Screw Cap | |||||

| Rinsing Pressure(MPa) | 0.2~0.25 | |||||

| Water Consumption of Rinsing(Kg/h) | 600 | 700 | 1500 | 1800 | 2500 | 3000 |

| Air Pressure(MPa) | 0.4 | |||||

| Air Consumption(m3/min) | 0.3 | 0.3 | 0.4 | 0.4 | 0.5 | 0.55 |

| Total Power(Kw) | 3 | 3.3 | 4.2 | 5.6 | 6.4 | 9.8 |

| Overall Dimensions(L×W×H)(mm) | 2260×1600×2350 | 2350×1900×2350 | 3300×2300×2400 | 4100×2850×2400 | 4250×3200×2400 | 5750×3750×2400 |

| Total Weight(Kg) | 2800 | 3000 | 5000 | 6500 | 8000 | 9000 |

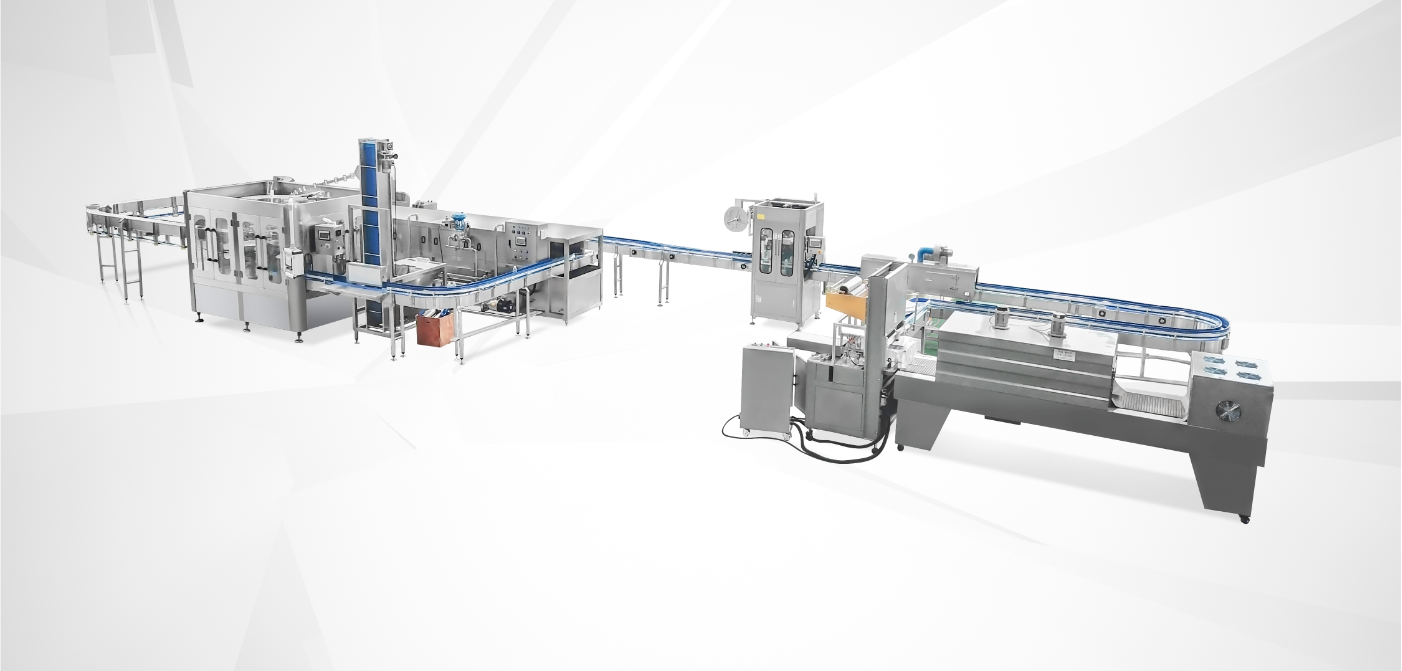

Your system from Planet

—— The entire production process from one source.

The water treatment system is used in Mineral water and other bottled water, water for food and beverage production.

Blow molding system is characterized by its reasonable structure, lower power consumption, good stability, flexible blowing process and simple operation, especially on the production of drinking water, carbonated beverage and other common PET bottles, as well as heat-resistant bottle, mid-temperature PET bottle, sterile cold PET bottle.

Here you can choose the best machine for your line.