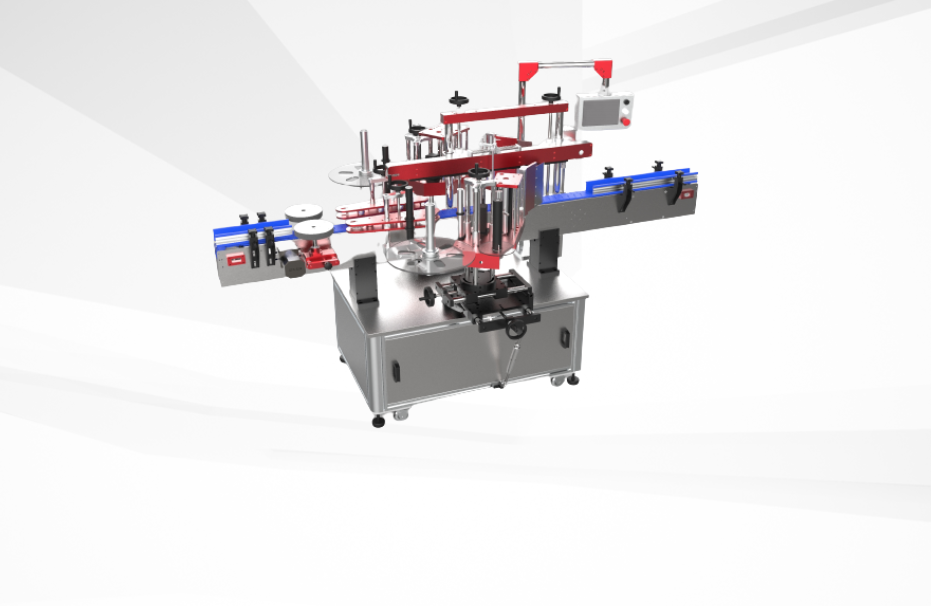

NO. | NAME | 150 | 250 | 300 | 400 |

1 | Input Power | 2.5KW | 3.0KW | 4.0KW | 4.0KW |

2 | Input Voltage | PH3, 380V220AC | PH3, 380V220AC | PH3, 380V220AC | PH3, 380V220AC |

3 | Production Efficiency | 150Bottles/min | 250Bottles/min | 300Bottles/min | 400Bottles/min |

4 | Size of Host Machine | 2100L *850W*2000H | 2100L *1100W*2000H | 2600L *1100W*2200H | 2600L *1100W*2200H |

5 | Bottle diameter | 28mm - 120mm | 28mm - 120mm | 28mm - 120mm | 28mm - 120mm |

| 6 | Length of Label | 30mm - 250mm | 30mm - 250mm | 30mm - 250mm | 30mm - 250mm |

| 7 | Thickness of Label | 0.03mm-0.13mm | 0.03mm-0.13mm | 0.03mm-0.13mm | 0.03mm-0.13mm |

| 8 | Paper tube diameter | 5"-10 adjustable | 5"-10 adjustable | 5"-10 adjustable | 5"-10 adjustable |