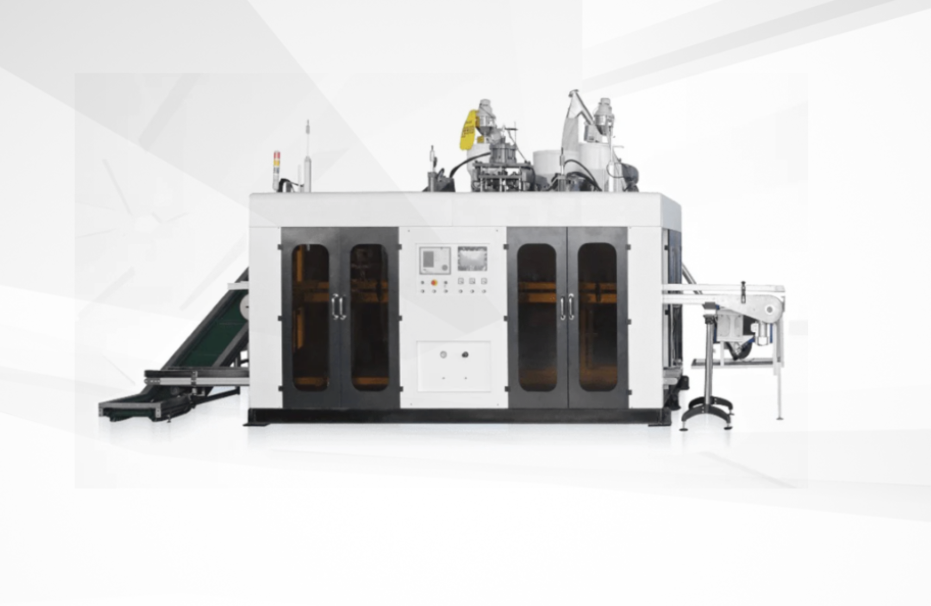

Item | Description |

Working voltage | Three-phase-five –line 380V/50Hz |

Control voltage | DC24V |

Air compression pressure | 0.6~0.8Mpa (without oil without water) |

Air consumption | 100-120NL/min |

Pipe Joint Size | Φ10 |

Packing speed: | 15-20 pkgs/min |

Shrink chamber dimension: | L×W×H=1800×650×450(mm) |

Shrink temperature: | 130℃~230℃ |

Packing : | LDPE (dust & static electricity removed) |

Width of film roll: | ≤580mm |

Thickness of film: | 0.07~0.10mm |

Diameter of film roll: | ≤350mm |

Film reel diameter: | 76mm |

Working noise: | ≤65dB |

Installed capacity: | 55KW; |

Average power: | 42KW |

Total weight: | 4500kg |