200ml-2L Bottled Water Filling Machine

3-10L Water Filling Machine

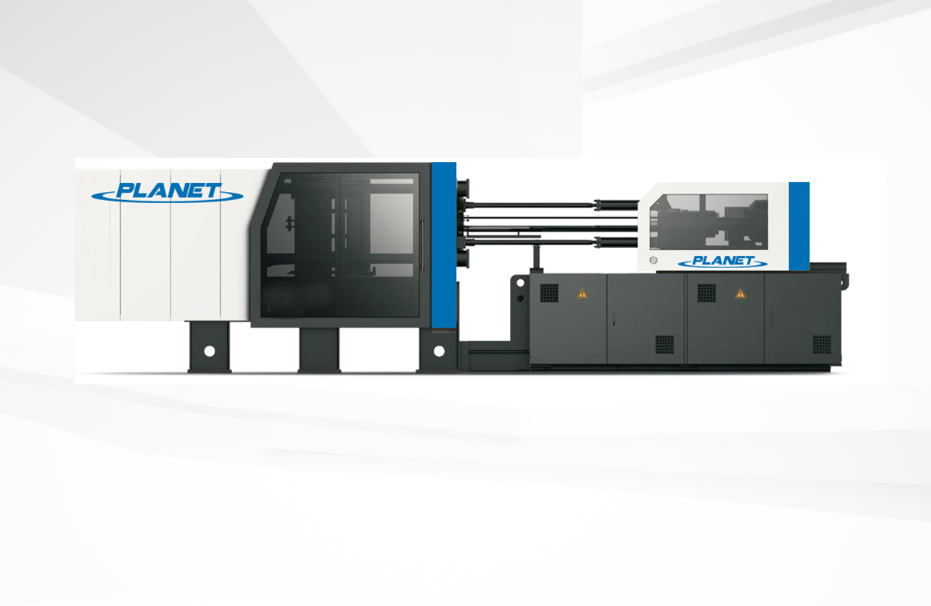

Plastic Injection System

Glass Bottle (Beer) Filling Machine

Glass Bottle Filling Machine

Pure water treatment system

Can Beverage Filling Machine

Hot (Juice) Filling Machine

Carbonated Soft Drink Filling Machine

Linear PET Blow molding system (variable pitch)

Linear PET Blow molding system (fixed pitch)

Antiseptic Plastic bottle filling machine

Linear weighing type filling machine

Liner piston type filling machine

Liner Iron Drum filling machine

5 Gallon Barreled Water Filling Machine

Linear Type Film Shrink Wrapping Machine

L Type Film Shrink Wrapping Machine

Hot Melt Glue Labeling Machine

Carton Case Packing Machine

One Piece Film Shrink Wrapping Machine

Automatic Sleeve Labeling Machine

Can Depalletizer

Rotary PET Blow molding system

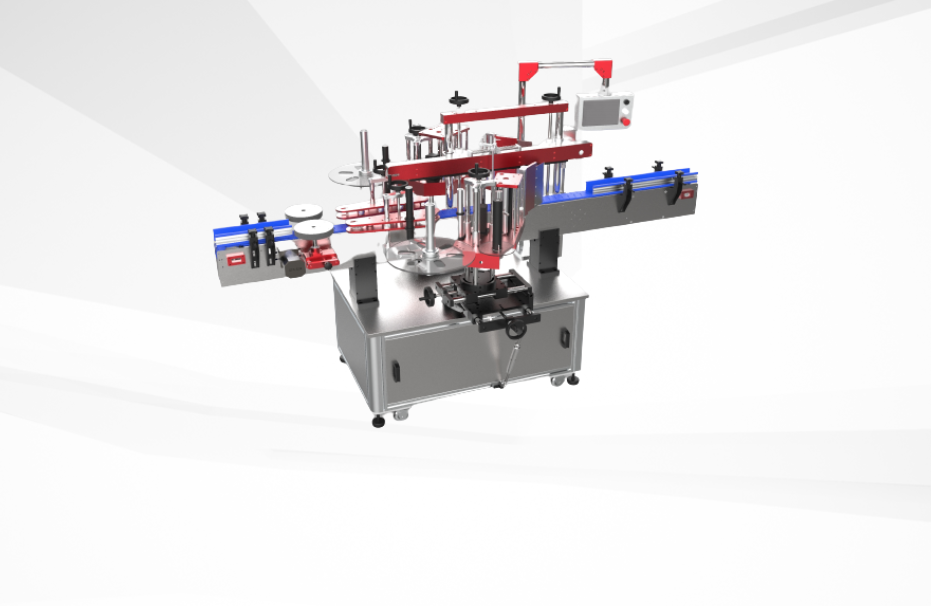

Self-adhesive Labeling Machine

Juice Pre-treatment System

Carbonated drinks pre-treatment system

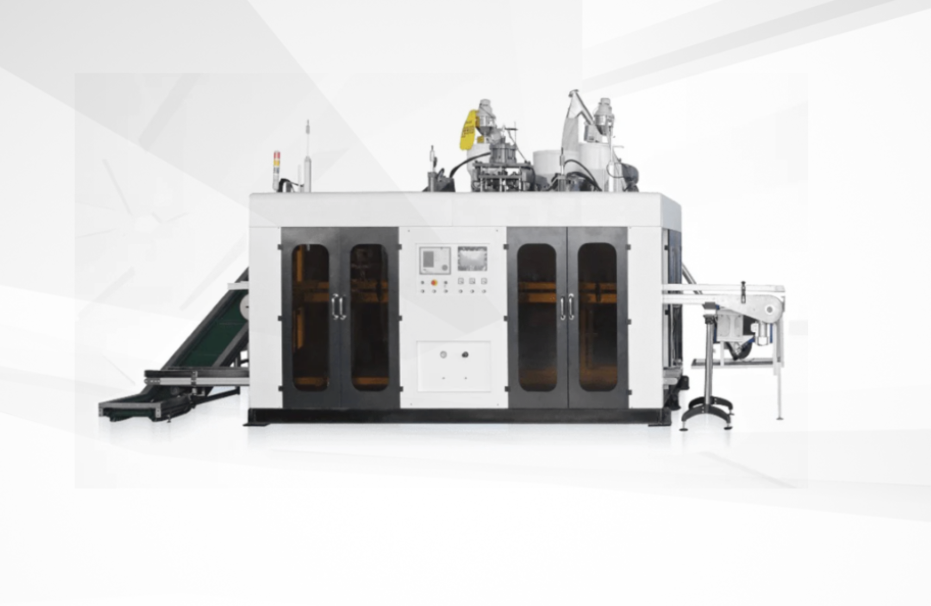

Extrusion Blow Molding Machine